ZS-BD Roller Transfer Machine (Professional Edition)

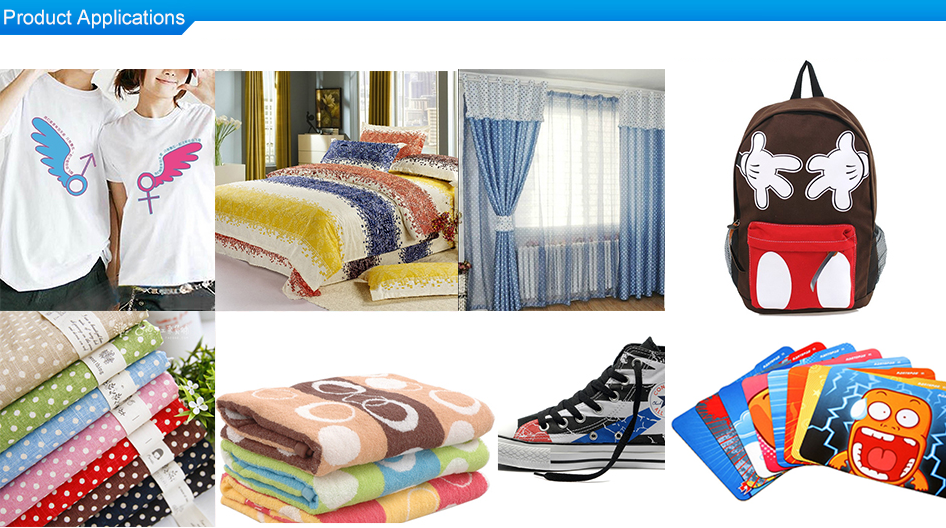

Through the plane transfer printing machine and pre-ordinary roller transfer printing to be improved to solve the problem of color is not deep enough and not uniform enough to solve a variety of one-time digital printing, packaging fabrics, pieces, clothing, mouse pad, will not produce color , Ghosting, and so the transfer of the previous problems.

| Product number | ZS-BD1700 | ||

| Drum diameter | Double drum 420mm | Effective transfer width | 1700mm |

| The drum is actually wide | 1900mm | Blanket production materials | Imports of US "DuPont" blankets |

| heating method | Heating pipe heating oil heat | Machine power | 30KW |

| Machine current | 52A | Pressurized way | Pneumatic pressure |

| Winding method | The inflatable shaft receives the paper and the backing paper | Host size | 2500×1000×1500(mm) |

| Work frame size | 3500×1720×900(mm) | Machine size | 4500×2500×1500(mm) |

1. US imports "DuPont" blanket, the thickness of 10 MM, transfer effect, and long service life.

2. Using 100% seamless tube roller, cylinder cylindrical / internal precision lathe, cylindrical cylindrical grinding Seiko, and then iron dragon, to ensure that the temperature of each point in line. Optional single-layer drum and double drum, double-roller heating more uniform, no color transfer effect, saving 20% ??-30%. Taiwan stainless steel heating pipe direct heating layer, 45 minutes can be heated to 200 degrees.

3. The main wall board with 10 PCT thick steel plate production.Wire cutting, high precision, the error is smaller.

4. Adjust the offset shafts of each precision lathe, grinding, and then platinum. Error control in the 2 C. Within the normal work of the blanket does not go astray.

5. Electrical control. High-quality digital display, temperature, time control, higher accuracy.

6. Imported variable-speed motor, according to the transfer of different materials to adjust the speed.

7. Carbon brush conductive heating, conductive properties more stable and safe.

8. Pneumatic pressure / hydraulic pressure function. Better transfer effect, the color deeper and more vibrant.

9. Blanket automatically separated when the blackout or shutdown, the blanket automatically with the roller separation, better protection blankets, extend the life.

10. Conveyor belt transfer function. Product transfer, after the conveyor belt to the back of the shelf, more labor saving. Optional up and down conveying function, more efficient.

11. The machine adopts 3 put 2 receive function. Can be customized according to customer requirements. Optional inflatable shaft income / release, positioning better.

12. Multi-function oil temperature roller transfer printing machine can do: pieces, cloth (horsepower) and clothing.